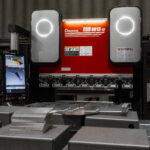

Advanced Forming Technology for Complex Requirements

Our metal forming services utilize cutting-edge technology to create precise bends, forms, and shapes to meet your exact specifications. Our advanced equipment includes 5-axis backgauge that speeds set-up for complex parts and high-speed movement on all axes ensures that the gauge fingers are positioned as quickly as the operator positions the part.

Our Metal Forming Capabilities:

- Independent servo drives for “L” axis allow tapered bends

- Unprecedented positioning repeatability of +/-0.0001″

- Tool navigator software positions backgauge where each tool needs to be installed, shortening the tool installation process

- Precision forming for complex geometries

- Consistent accuracy across production runs

- Versatile material handling capabilities

Applications

Our metal forming expertise serves a wide range of industries and applications:

- Custom enclosures and cabinets

- Precision brackets and mounts

- Complex structural components

- Architectural elements

- Equipment housings and panels

- Custom fabricated assemblies

Quality Assurance

We maintain rigorous quality control throughout the forming process, utilizing advanced measurement techniques and inspection procedures to ensure every part meets specifications. Our ERP System Software provides job tracking from start to finish and inventory tracking, ensuring complete process control

Collaborative Approach

Our team works closely with you to understand your specific requirements, recommending the most effective forming techniques to achieve your desired results while optimizing for production efficiency and cost-effectiveness.