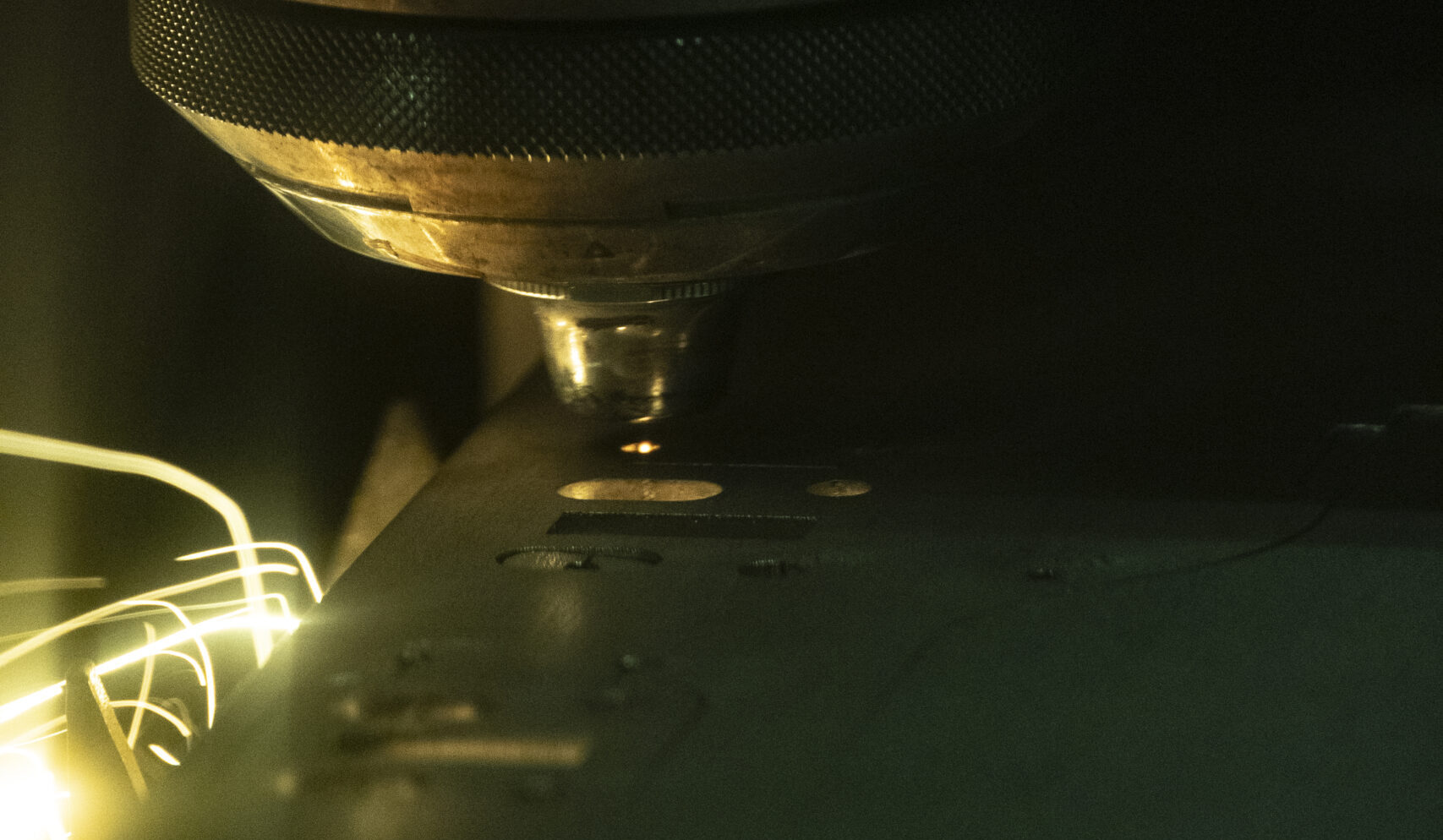

Versatile Cutting Without Heat Distortion

At Marsam Metalfab, we can machine a wide range of materials from metal and composites to glass and plastic. We are able to cut over a large area and through thick materials. Water cutting is precise and does not create heat-affected zones, making it ideal for materials sensitive to heat distortion.

Advantages of Our Water Cutting Services:

- No Heat Distortion: Perfect for heat-sensitive materials

- Exceptional Material Versatility: Cut metals, composites, plastics, glass and more

- Superior Edge Quality: Clean, burr-free edges requiring minimal secondary finishing

- Thick Material Capability: Precision cutting through substantial thicknesses

- Environmental Friendliness: No hazardous gases or liquids in the cutting process

- Complex Shape Capability: Intricate designs with tight tolerances

Applications

Our water cutting services are ideal for:

- Thick metal components

- Heat-sensitive materials

- Composite materials

- Precision parts requiring no thermal distortion

- Complex contours and intricate designs

- Material combinations and layered materials

Quality Control

Our engineers utilize the latest CAD technology and industry best practices to develop comprehensive designs that consider every aspect of your project, from material selection to assembly methodologies.

Customer-Focused Solutions

Whether your requirement is a single piece prototype or a 1000 piece run, our major objectives are excellence in quality, service, and customer satisfaction. Our water cutting experts collaborate with you to develop solutions that precisely meet your needs.