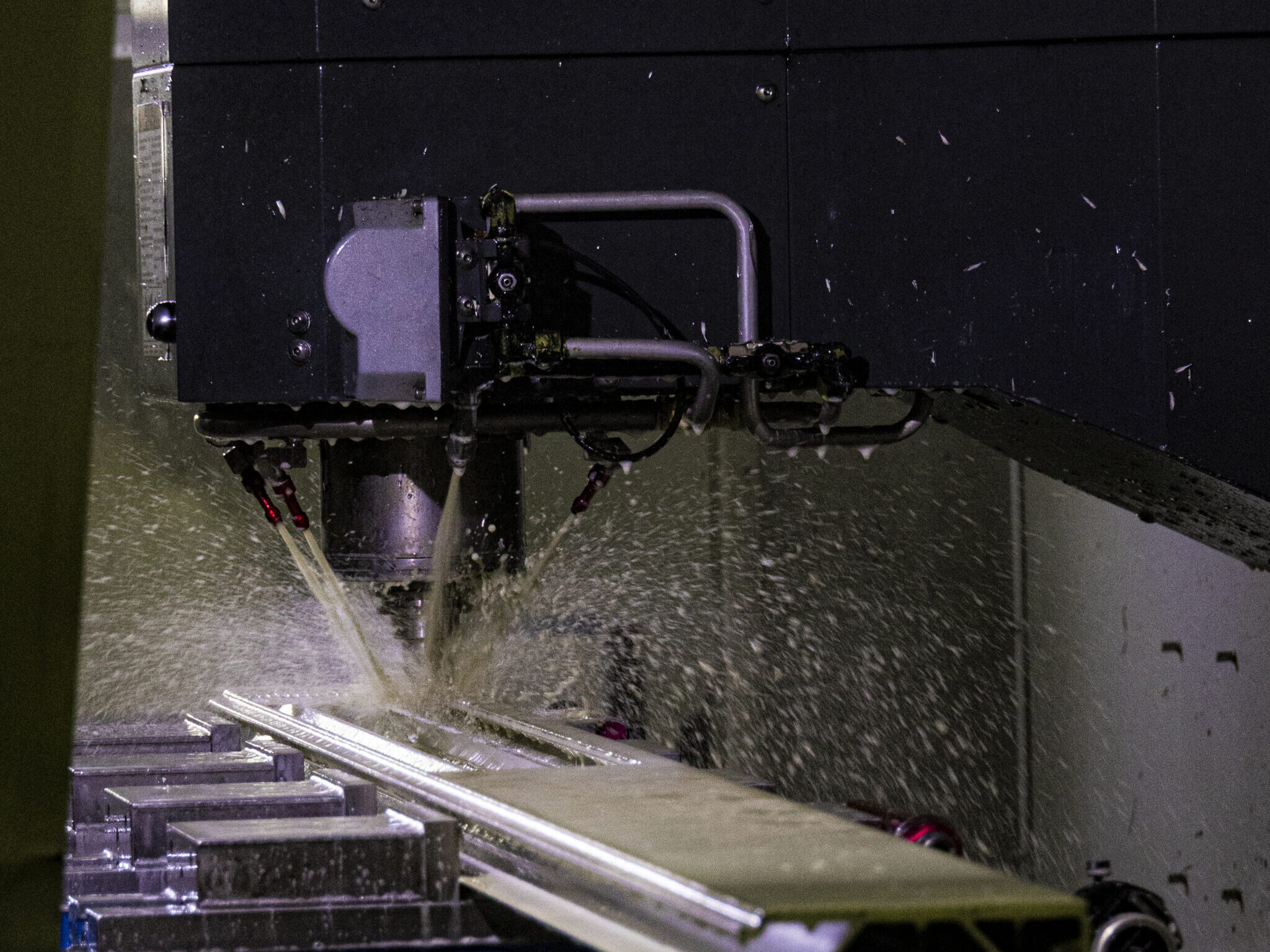

Advanced Manufacturing Precision

Our Machining capabilities allow for a single piece run to large production runs with consistency and quality. Using advanced CNC technology, we deliver precision-machined components that meet the most demanding specifications.

Our CNC Machining Capabilities:

- Precision Control: Computer-controlled precision for repeatable accuracy

- Multi-Axis Machining: Complex geometries and contours

- Material Versatility: Experience with various metals and alloys

- Tight Tolerances: Exacting specifications consistently maintained

- Surface Finish Options: Various finishes to meet functional and aesthetic requirements

- Production Flexibility: From prototypes to high-volume production

Applications

Our CNC machining services support diverse applications including:

-

- Precision components

- Custom fittings and hardware

- Complex mechanical parts

- Specialized tooling

- Custom fixtures

- Production components

Quality Control

All welding operations adhere to strict quality control procedures, including material certification tracking and comprehensive inspection processes. We maintain detailed documentation of all welding procedures and certifications.

Quality Assurance

Every machined component undergoes comprehensive inspection, with first and last article reports throughout all production processes. Our quality control procedures ensure consistent precision across production runs of any size.

From Design to Production

We work closely with your team to optimize designs for machining efficiency while maintaining critical specifications. Our expertise in material selection, machining techniques, and quality control ensures superior results for each project.